Our Products

ENCAP ANTISCALANT

Repuls internationals is manufacture of Antiscalant with organic polymer with name “ ENCAP” brand from 2019,in Chennai.

Antiscalant is a pretreatment water additive for reverse osmosis system that is highly effective in preventing the membranes from scaling. Before the feed water enters the reverse osmosis membrane, an antiscalant is injected into the water and sent the through the system.Our antiscalant works with high silica level also and give better result to the customers.

- Suitable for reverse osmosis (RO) and Ultra filteration(UF) Membranes.

- Excellent for Reactive Silica Antiscalant

- Allows high recovery rate

- Encapsulate scaling salts

- Inhibits common scales like calcium carbonate / sulphate,

- Barium / Stronium sulphate, Silica, Calcium phosphate, Iron & Maganese.

- Packing : 5kgs/10kgs/25kgs

Activated Carbon

PRODUCT CHARACTERISTICS:

| First | Powder, Pellets Granules |

| Grade | Liquid phase or de-colouring carbon.Gas phase or vapour absorbent carbon. |

| Iodine Value€ | Type |

| certification | NFS Certified |

Product Introduction

Activated carbon is a unique and effective agent for purification and for isolation and recovery of trace materials. During the last two to three decades, treatment with active carbon has become an important unit process for separations and purifications in the food, pharmaceuticals, sugar, chemical and other processing industries.

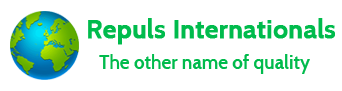

Sewage Treatment Plant :

Intruduction

Sewage Treatment Plant process was designed to treat domestic waste water (gray water) with an anticipated BOD of 450mg/l. The processes (procedure) adapted are purely biological -i.e. reducing the BOD or organic matters using different strains of beneficial bacteria in two steps followed by particle filtration and gas absorption. Sterilization achieved by using chlorine. For this plant Using Aerobic Method with air and using media.STP is Main process to convert sewage water into Gray water using Aerobic and Anaerobic Methods.

Type STP:

- FBBR Method

- MBBR Method

- Aerobic method with Ms Tank

- AnAerbobic STP with Civil Tank type

We done Large capacity into Small capacity type Sewage Treatment Plant.We done small capacity 1 KL into 10 KL and Large Capacity 50 KL (Kilo Litres) into 1 MLD (million Litres Per Day).

Effulent Treatment Plant:

Introduction :

Effulent Treatment Plant process was designed to treat Industrial Waste water with an anticipated COD of 450mg/l. The processes (procedure) adapted are purely Chemical Precipation -i.e. reducing the COD or organic matters using different strains of beneficial bacteria in two steps followed by particle filtration and gas absorption. Sterilization achieved by using chlorine.For this plant Using Chemical precipation and Aerobic Method with air and using media.ETP is Main process to convert Industrial Waste water into Purified water using Aerobic and Anaerobic Methods.

CapacityWe done Large capacity into Small capacity type Sewage Treatment Plant.We done small capacity 1 KL into 10 KL and Large Capacity 50 KL into 1 MLD (million Litres Per Day)

Reversis Osmosis Plant :

Introduction :

The water treatment plant offered is to produce treated water of highest quality, which meets all the requirement of Bureau of Indian Standard (BIS) IS 14543. It uses the state of art “Reverse Osmosis” treatment for the removal of unwanted dissolved minerals, organics and microbial contaminations. This first stage purification is followed by disinfection system consisting of U.V. to ensure water of the highest quality is produced as the end point.

Process :RO is mainly 5 Filterantion methods. They are as follow below

1.Sand Filteration 2.Activated Carbon Filteration 3.Membrane Filtration 4.Ozonation 5.UV (Ultra Violet Filteration )

CapacitySmall Capacity :10 liters Ro Plant into 50Litres Plant

Large Capacity :250 LPH into 10000LPH

ZERO LIQUID DISCHARGE :

Introduction :

ZLD is Process to Recover ETP and Industrial effulent to Purifies with RO and Evoporation almost to zero level.Many Industries Buliding Plant of ZLD in India

Process : RZLD is mainly 7 Filterantion methods. They are as follow below1.Sand Filteration 2.Activated Carbon Filteration 3.Membrane Filtration 4.Ozonation 5.UV (Ultra Violet Filteration )

Capacity5 KLD to 1 MLD

Iron Filteration Plant:

Introduction :

Iron Filteration is Mainly Pretileration and Iron Filter.Iron filter is a filled with Mi02(Magesnes Oxide).To mainly used for remove Ion minerals in Drinking water both Industrial and Commericial Purposes.

Type- Commerical Type

- Industrial Type

Water Treatment plant:

Introduction :

The water treatment plant offered is to produce treated water of highest quality, which meets all the requirement of Bureau of Indian Standard (BIS) IS 14543. It uses the state of art “Reverse Osmosis” treatment for the removal of unwanted dissolved minerals, organics and microbial contaminations. This first stage purification is followed by disinfection system consisting of U.V. to ensure water of the highest quality is produced as the end point.

Process :

RO is mainly 3 Filterantion methods. They are as follow below

1.Sand Filteration 2.Activated Carbon Filteration 3.Membrane Filtration 4.Ozonation 5.UV (Ultra Violet Filteration )

Softner Filteration System:

Introduction :

The water treatment plant offered is to produce treated water of highest quality, which meets all the requirement of Bureau of Indian Standard (BIS) IS 14543. Softner is to remove Ca and Mg Mineral salt in water Using Cation Resin And Its regenerated by Sodium Chlorides.

Process : RZLD is mainly 7 Filterantion methods. They are as follow below1.Sand Filteration 2.Activated Carbon Filteration 3.Membrane Filtration 4.Ozonation 5.UV (Ultra Violet Filteration )

Capacity:Commerical Type & Industrial TypeLab Instruments

BOD INCUBATOR

INTRODUCTION :

Cooling Incubators (BOD)are especially designed to Conduct life cycle testing ,shelf life studies,general incubation and refrigerated storage. Temperature range adjustable from 5.0 to 60 ‘C with Micro Controller Based Temperature Controller. Unique airflow system ensures even distribution of temperature.

Capacity

112 litres to 1000 litres

LAMINAR AIR FLOW

INTRODUCTION :

The Horizontal Laminar Air Flow Provides Product Protection within the Work area,which is confined by removable clear glass panels and stainless steel work surfaces.Work Area Sizes : 2 X 2’,3 X 2’,4 X 2’,6 X 2’,

Sailent Features :It Provides ISO class 5 (class 100 U.S. federal Standards 209 E)environment Within the Work Area that Complies With the latest IEST recommended practices. Perforated Stainless Steel Diffuser Screen Products the HEPA Filter and Maintain Uniform air flow velocity within the work area.

Filters : Aluminum framed High Efficiency Particulate air (HEPA)fiter,Efficiency 99.99% at 0.3 Micron.

AUTO CLAVE:

INTRODUCTION :

- System in Vertical Autocclave is introduced for first time in india.enables you to lift the lid easily and safely.It also reduces the loading height.

- 2. All models are made fully SS 304 construction.

Laboratory Autoclave are Widely used in Pharmaceutical,food,water,biotechnology industries and as also in Microbiology and R & D laboratory

Sailent Features Fully SS 304 Construction.

Micro Controller based PID controller with dual display for Temperature and time ,pressure Switch.

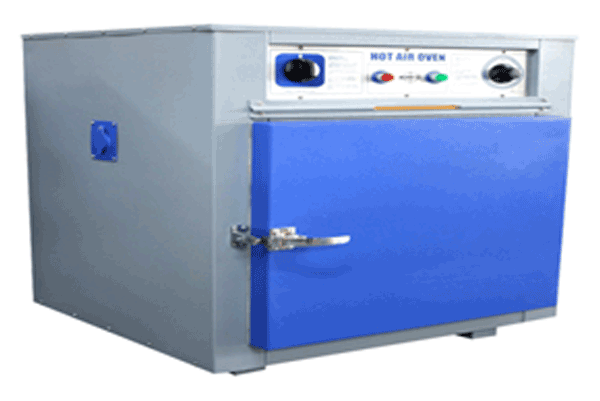

HOT AIR OVEN:

The Drying Oven are based on modern technology.They are more Compact and require less space.

Salient Features: CC

Double Walled ,outer of Mild Steel Powder Coated and lagged With glass wool’s

Bottom heaters covered by perforated Sheet and S.S Shelves.

Temp Range up to 250C.

Forced air circulation.

Complete with IQ OQ and PQ documentation.

Water Treatment Chemical

We are dealing branded glassware and chemicals likes BoroSil,Tarsons,Himedia,pure,Loba and Nice Chemicals.